Innovation is key to the success of the medical devices industry. Making revolutionary concepts come to life requires a trusted partner who can translate ideas into tangible prototypes and, ultimately, high-quality production parts. Influx Labs steps in to fulfill this crucial role, offering a comprehensive solution for medical device manufacturers seeking excellence in prototype manufacturing and CNC machine machining.

Influx Labs: From Dream to Prototype Medical Device Innovation Facilitated

For companies that manufacture medical devices that are in the business of medical devices, the process from initial concept to market launch is often complex. Influx Labs knows the importance of prototyping in this procedure. They provide a hospitable environment to turn your innovative ideas into testable prototyping that allows you to make improvements and collect feedback before committing large-scale production.

Influx Labs Expertise on CNC Machining

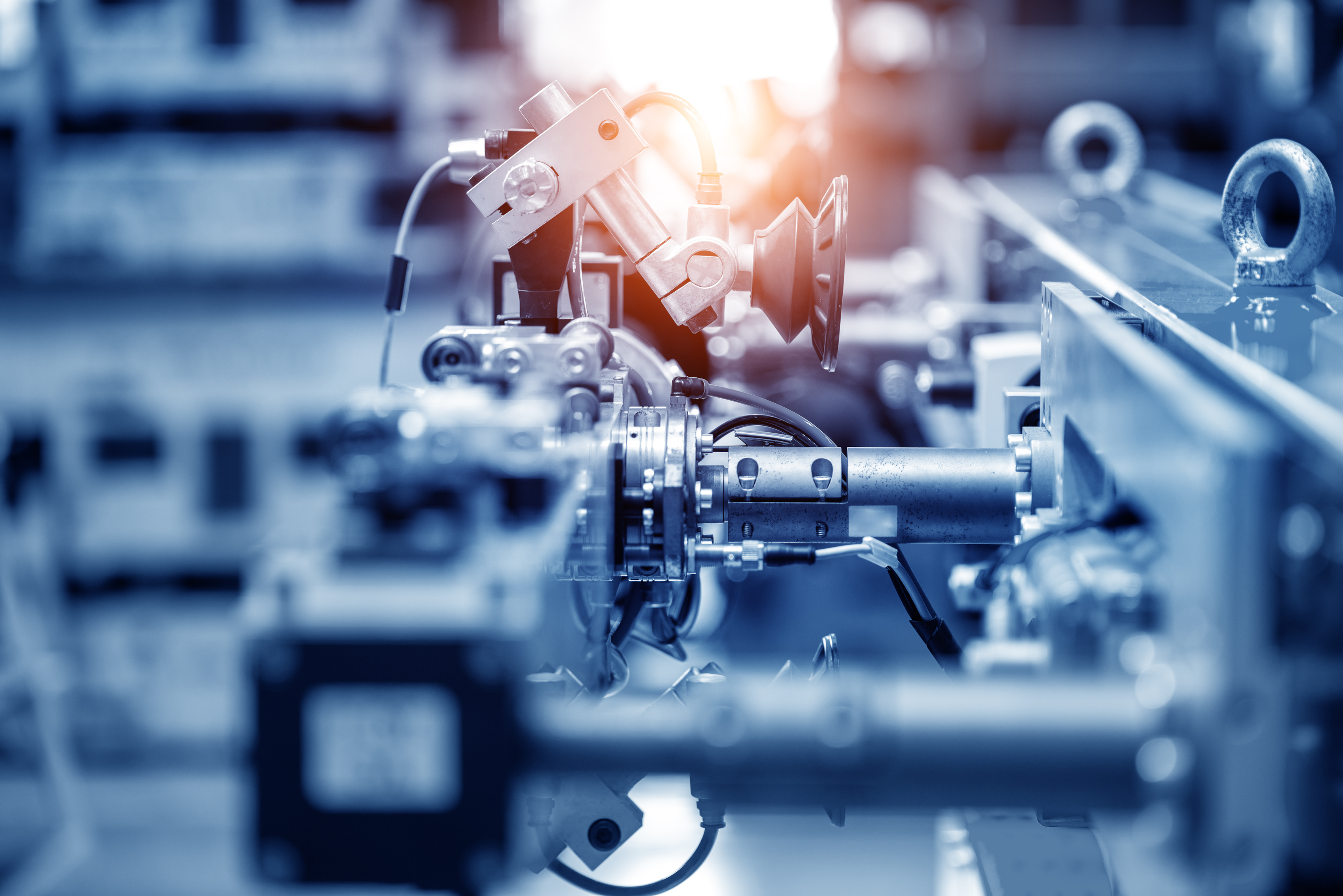

At the core of Influx Labs’ capabilities lies the state-of-the-art CNC cutting-edge technology. CNC (Computer Numerical Control) machineries employ computer-aided instruction to control precisely cutting tools, enabling the production of extremely precise and intricate parts. Influx Labs is able to make medical device prototypes as and production parts that conform to the most rigorous standards for medical devices.

Beyond Prototyping: Scaling Up for Production

Influx Labs’ services extend beyond the realm of rapid prototyping. Their experience in CNC machining allows them to seamlessly transition from prototype development to high-volume production runs. This means that they do not have to choose a separate manufacturer, streamlining the entire process while ensuring consistency between prototype and final product.

Certifications and traceability of material Quality assurance and traceability

Influx Labs recognizes the critical importance of quality in the field of medical devices. They employ a stringent system of complete traceability of the materials used throughout their process. This ensures you have complete visibility of the materials used in the production of your prototypes and parts. Influx Labs also offers material and finishing certificates on demand. This provides security and allows you to meet the strict requirements of regulatory compliance.

Why choose Influx Labs for your medical device requirements?

Influx Labs stands out from other prototype and machining companies due to a number of factors. Here are some reasons they’re an excellent partner for medical device design:

Dedicated to Medical Devices: Influx Labs understands the unique demands in the field of medical devices. They possess the expertise and knowledge required to produce medical-grade components that are of the highest quality.

Precision Engineering: The advanced CNC machining capabilities of Precision Engineering ensure consistency and precision in the manufacturing of safe and effective medical products.

Seamless transition: Influx Labs offers a single-stop solution for manufacturing and prototyping, which saves you time and money in locating separate vendors.

Quality and commitment From traceability of materials to certifications Influx Labs prioritizes quality control making sure that medical devices adhere to the strictest requirements.

Influx Labs accelerates your medical device development process

Influx Labs’ expertise in prototyping and CNC machining enables medical device manufacturers to bring innovative ideas to fruition faster and more efficiently. When you partner with Influx Labs, you gain access to:

Reduced Risk: Prototyping enables you to detect issues and fix them early in the design process, thus reducing the risks associated with full scale production.

Influx Labs’ streamlined prototyping and production allows you to speed up the time to bring your medical device to market.

Advanced Design Refinement Using Physical prototypes provide thorough evaluation and feedback from users, which allows you to improve your designs more confidently.

Influx Labs is the perfect partner to unlock the potential and power of rapid prototyping, high-precision CNC manufacturing and other innovative technologies. See your innovative medical device concepts transform into reality creating the future of healthcare.